3D scanning: essential for efficient and controlled industrial Retrofit.

Modernizing, refurbishing, or increasing the capacity of an existing industrial facility is a complex and demanding task. Before planning new layouts, it is essential to analyze all existing elements in the environment to determine their position, shape, and dimensions. However, manual on-site surveys are often time-consuming, tedious, costly, prone to inaccuracies, and incomplete, especially in areas that are difficult to access. Even a minor error can lead to construction delays, significant cost overruns, and production stoppages.

3D scanning is not just a precision tool: it lays the foundations for the industry of the future. Modeling your facilities today means preparing for tomorrow: simulating scenarios, anticipating future adaptations, facilitating site lifecycle management, etc. 3D data is becoming a sustainable digital foundation for continuous innovation.

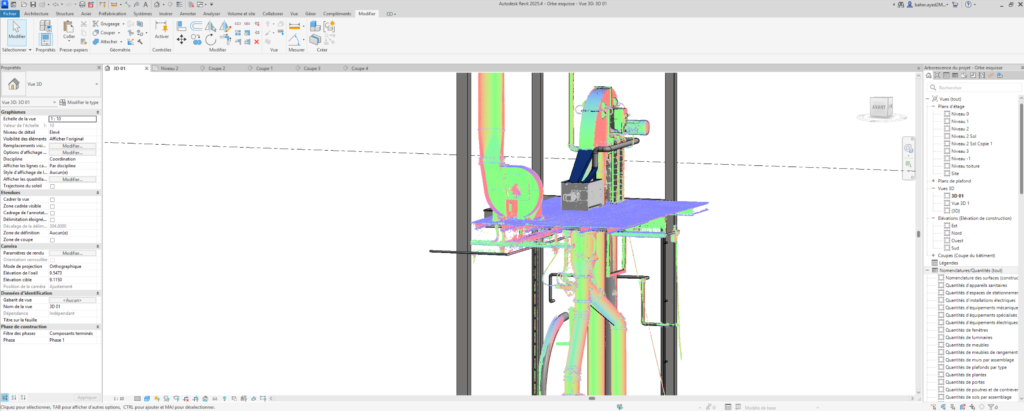

At Igenium, we know from experience that the complexity of the industrial environment, its clutter, and the many constraints identified in the intervention area must be mastered. That’s why we have made 3D scanning an everyday tool in our BIM process and an essential ally in our project approach. BIM (Building Information Modeling) is a collaborative working method based on a digital model that centralizes all project data (technical, temporal, and financial information). It simplifies coordination between the various stakeholders, improves decision-making, and significantly reduces errors from the design phase onwards.

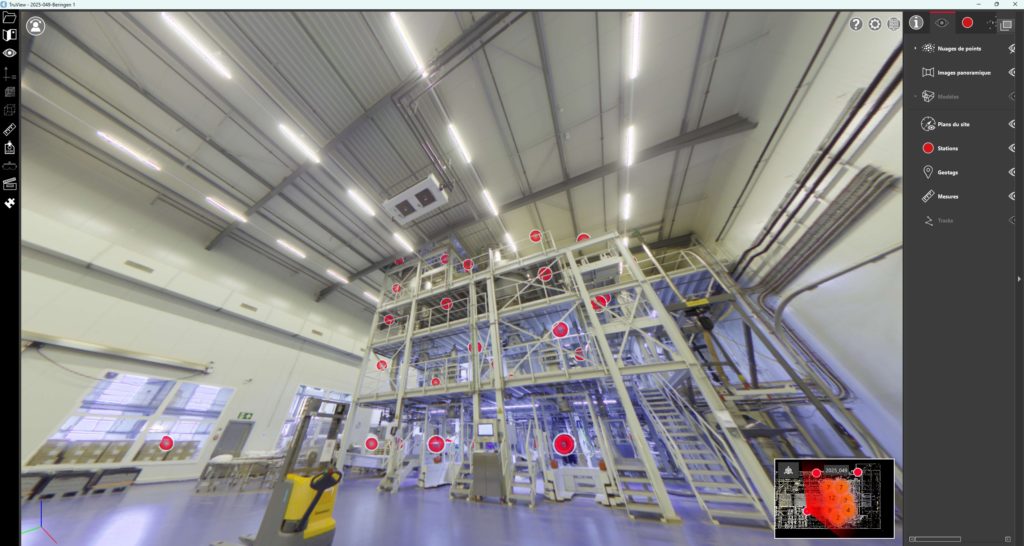

Thanks to high-precision 3D terrain or drone scanning technology, we can quickly obtain a detailed and accurate view of the industrial environment. This allows us to generate a 3D model that will then serve as the basis for the BIM digital twin. Directly integrated into our BIM digital model, this meticulous modeling allows us to anticipate existing constraints, plan reliably, and limit technical uncertainties from the design phase onwards.

As a trusted partner for your turnkey industrial projects, we manage each stage, from design to completion, with strategy and rigor.

The benefits of 3D scanning, the digital twin of your industrial facility.

Thanks to comprehensive 3D modeling of your facility, we guarantee a competitive advantage from the start of the project by:

- Controlling our projects by collecting accurate and reliable data on the environment and verifying that the new equipment will integrate perfectly without any surprises during the assembly phase.

- Optimizing resources by speeding up measurements, simulating dismantling and installation stages, and minimizing errors, delays, and production stoppages.

- Smooth coordination between teams (maintenance, engineering, design) thanks to a centralized, shared model that serves as a common reference.

- Preservation of intervention history, with each modeled element archived to track what has been done, thus facilitating future maintenance operations and data recovery.

- Productivity per square meter, thanks to the precision and global visualization provided by 3D scanning, each square meter of your industrial site is revalued. We optimize not only the space required for equipment installation, but also traffic flow, safety, and storage space.

Industry 4.0 vision – expertise recognized by our customers

At Igenium, innovation is at the heart of our support. By integrating industrial digitalization tools such as BIM, we bring tangible added value to your projects and aim for sustainable performance.

Our approach is based on a structured methodology that has been proven on numerous industrial projects. It streamlines operations, improves the reliability of field data, and significantly reduces human error.

Clients such as Nestlé, Pronatec, Sabarot, and many others already trust us to manage their projects with precision and efficiency.

Insurance dimension: 3D as a safety net

Industrial insurance coverage now includes the concept of business continuity. In the event of a disaster, having a 3D scan (even a partial one) changes everything:

- Faster Disaster Recovery Plan (DRP): accurate restoration of the initial state, easier identification of areas to be treated, accelerated restart of production

- Digital twin: support for insurance claims, visual and technical evidence in the event of a dispute

- Reverse engineering: possibility of reproducing or repairing a part or sub-assembly identically

- Proof of value for compensation: all surfaces and equipment are modeled to date, a key argument when dealing with the insurer

3D scanning is therefore a real safety net for your company, reassuring decision-makers, investors, and insurers.

Want to find out more?

👉 Our experts are here to discuss your challenges and work with you to develop an effective industrial modernization strategy, supported by 3D scanning and BIM tools.